3D Printing in Education | Frequently Asked Questions

Have you ever wanted to know how other teachers run their 3D printing classes? Do they allow students to choose the materials? Do students operate 3D printers? Well today you're in luck! We asked 17 of our pioneer teachers a series of questions based on how they use 3D printing in their classroom. With each question, you'll be shown a pie chart of the questionnaire results across the board, together with some key comments made by the educators.

26th February 2022 • News

Just to give you an idea of what to expect – there were a very broad range of answers, which confirms that there isn’t a ‘right way of doing things’. Our aim is to provide you with varying opinions that guide you in choosing your own processes and strategies for 3D printing in the classroom.

Let’s get to the results!

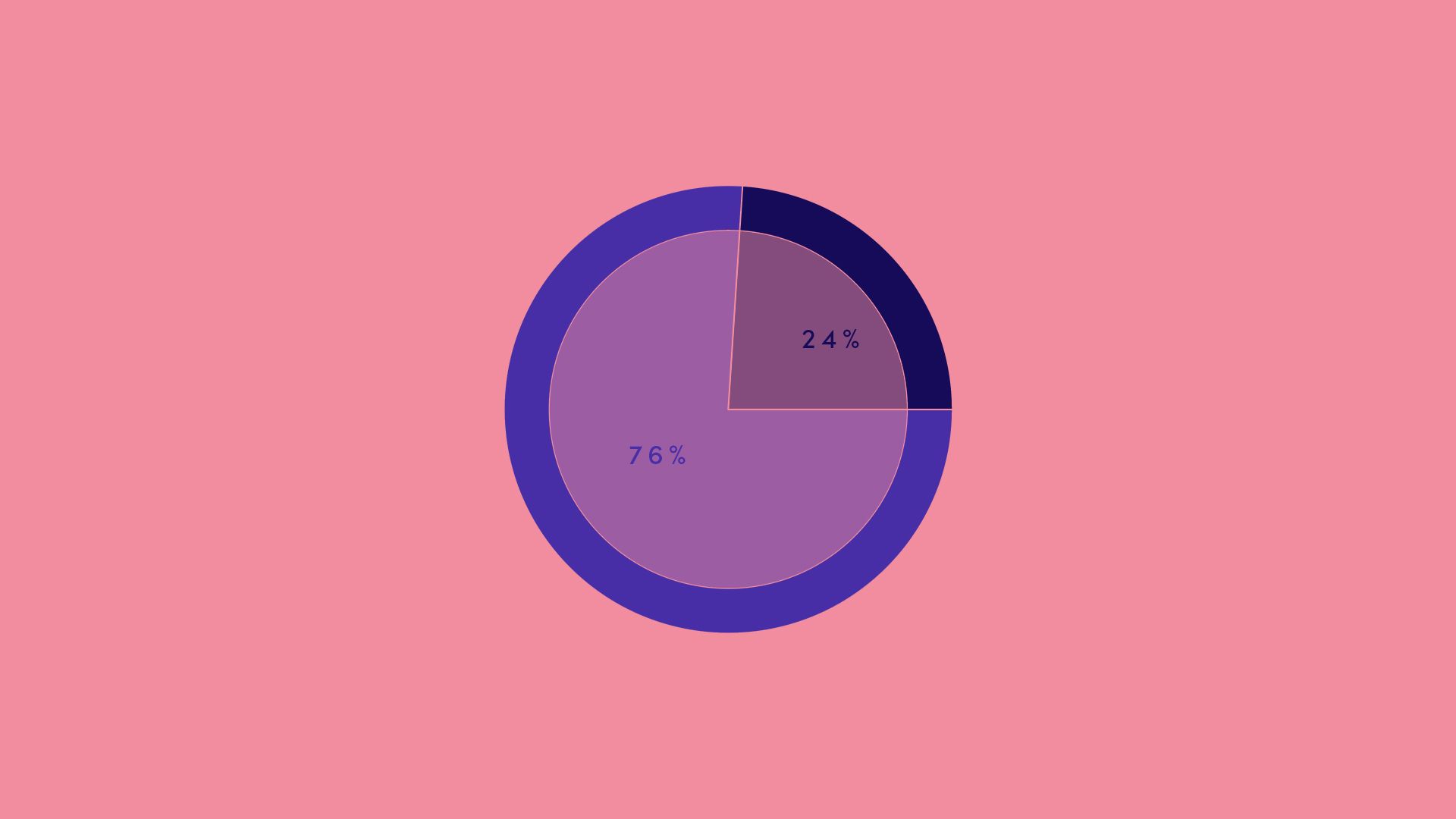

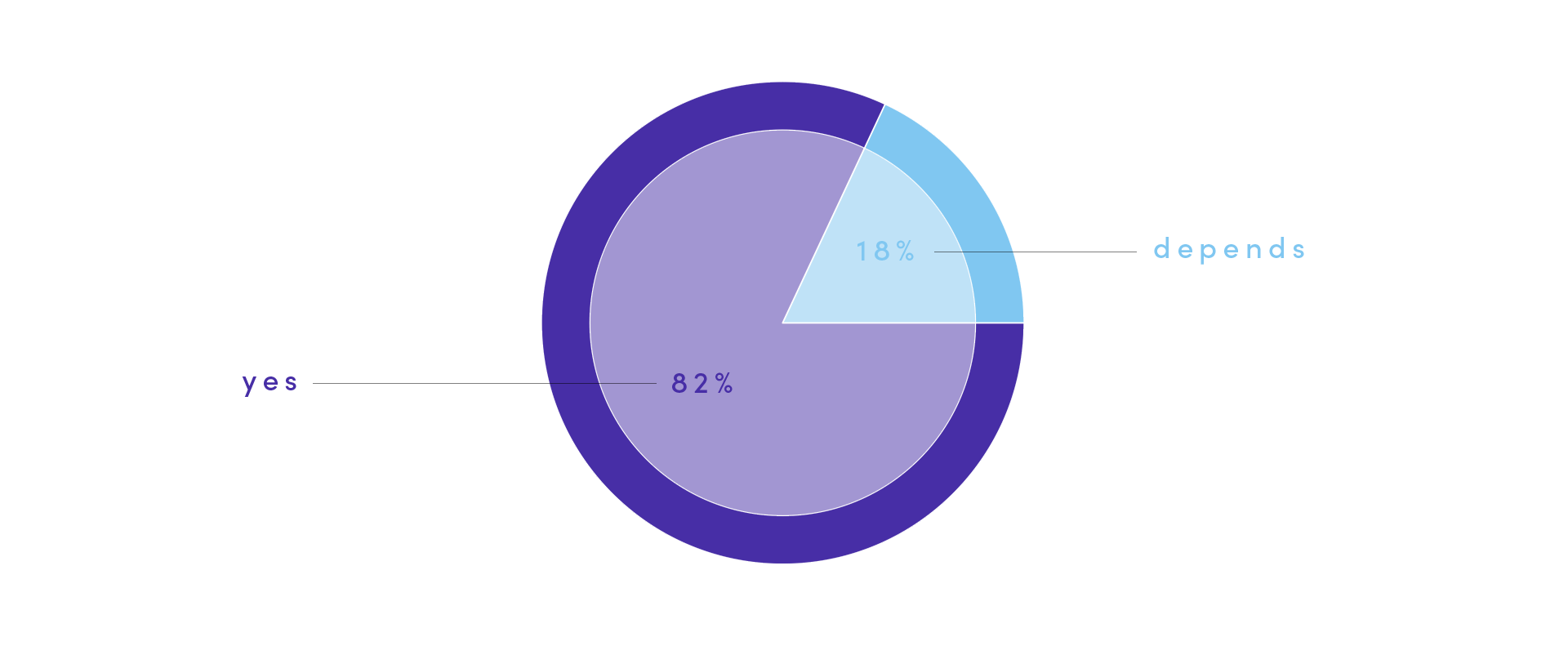

Q1: Do you keep your 3D printers running overnight?

“We have done risk assessments and the numerous thermal cutouts on our printers and the set up where we print means we think the risk rating is low”. Ed Charlwood, Head of Design & Technology at Nottingham High School.

“We have done risk assessments and the numerous thermal cutouts on our printers and the set up where we print means we think the risk rating is low”. Ed Charlwood, Head of Design & Technology at Nottingham High School.

“I have left printers running through the night on multiple occasions with no safety issues. With that being said it can be a surprise when you return to the classroom the next morning and your print was a fail! When run the 3D printers throughout the day we have developed an ear to catch the sounds of snags or simply visually seeing that a print is not working and getting to start over”. Lynette Curzon, EAST Facilitator at Westwood Elementary

“I have kept my printers running over night if there is a large print and I start it early enough in the day that I am confident it won’t fail over night. I usually do this when I have a large number of items to print. This is often the case since I teach grades 3-8”. Ron Nober, Technology/STEAM Teacher at Southampton Township Schools

“I will only let a print run overnight if if starts off strong and I am confident it will be able to finish. If I can avoid running it overnight I will. So it is only if it is needed soon”. Jim Cairns, Engineering Design Teacher at Bellevue Christian School

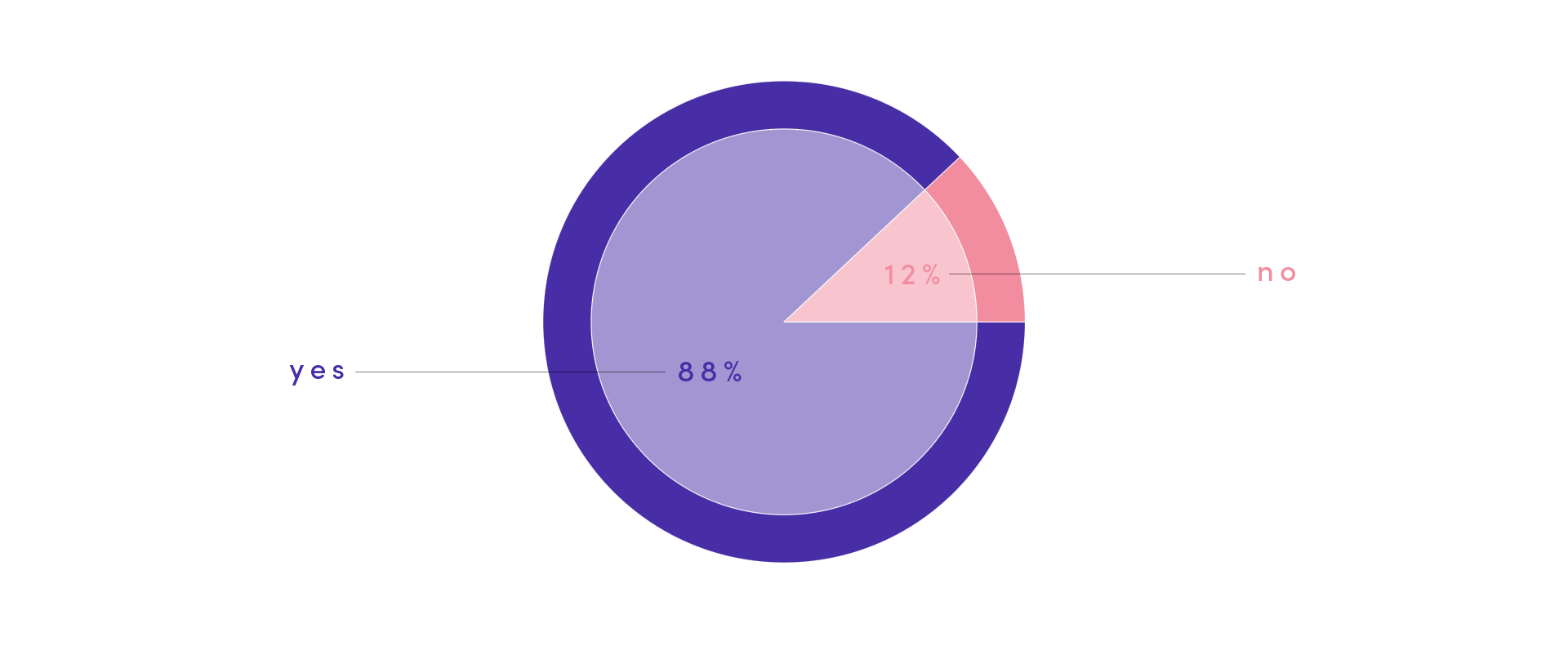

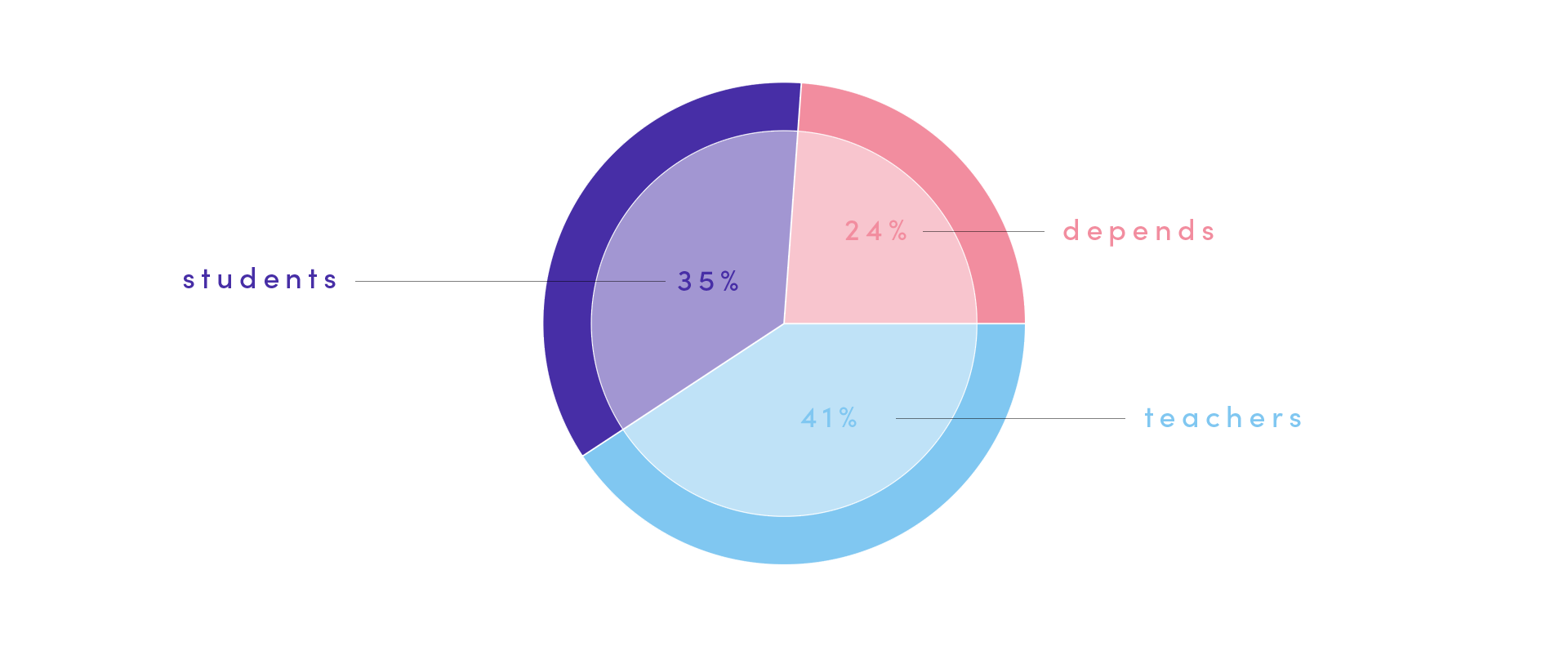

Q2: Do you let students handle/operate your 3D printers?

“Absolutely. Taking charge of one’s own learning is one of the “big ideas” of constructionism, so we encourage students to experience every stage of the printing process, from design to printing, and loading/changing the filament”. Patrick Benfield, Innovation Director at Magellan School

“When I had fewer students, they had more access to actually running the printers. Now that I have an assistant and much longer print queues due to many more classes, it isn’t as practical to have kids operating the machines”. Linda Dimitrov, МSHS D & T teacher at Anglo-American School of Sofia

“Yes I do. The students who are handling the printers are the ones that have been with me for two years. They help the younger students with their printing”. Michele Brezovec, Expanding Horizon Program Teacher at South Meadow School

“Yes, I teach my students to not only operate the printers, but also to troubleshoot so they can fix them. I teach junior high and I want the kids to get experience with everything involved in 3d printing if they want to learn about it”. Carrie Beach, EAST Facilitator at Washington Junior High School

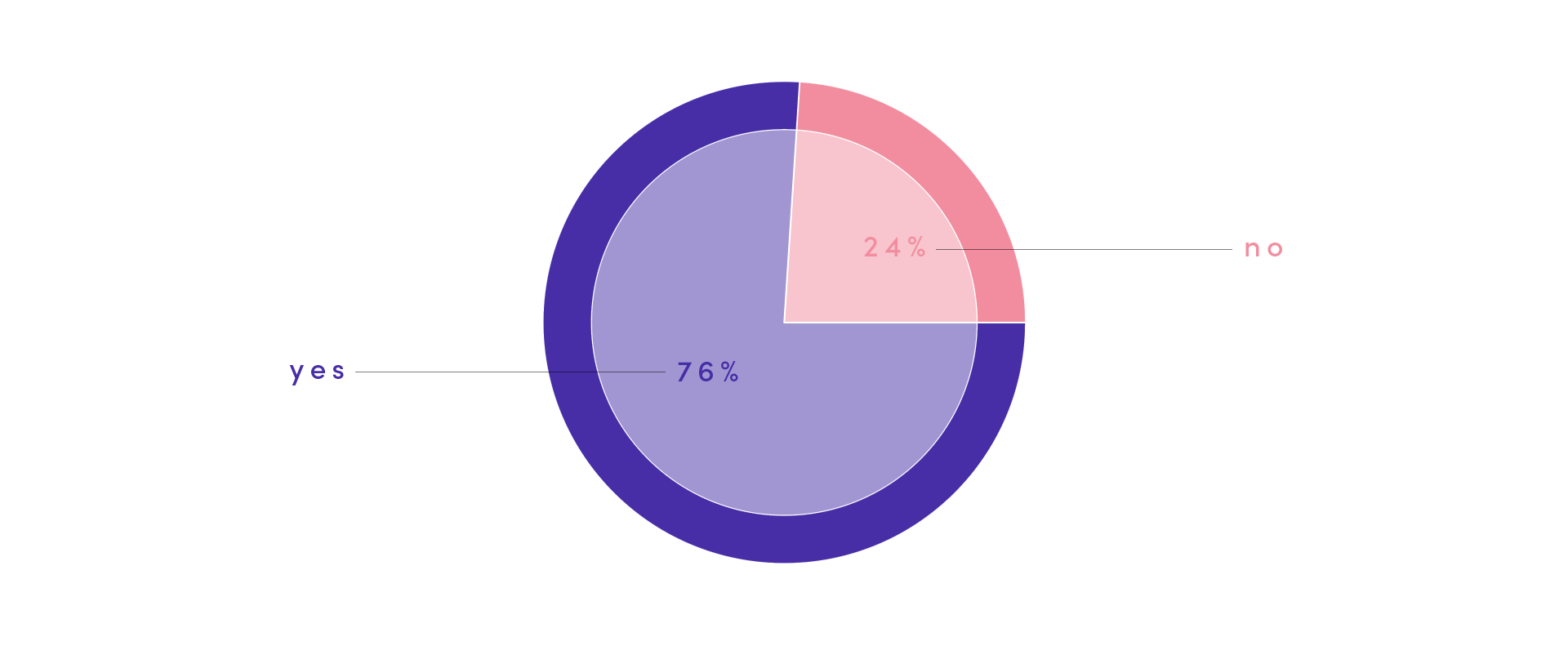

Q3: Do students generally work in teams or individually when working on 3D printing projects?

“I find for skill building they need individual accountability. But for the assistive devices Make:able challenge I have them work in groups of five with clear roles and it works well. For PrintLab’s balloon powered dragster and self watering planter lessons, I have them work in pairs to reduce my 3D printing load”. Jim Cairns, Engineering Design Teacher at Bellevue Christian

“I have my youngest students (5th graders) do a project on their own, but for my engineering class, students work in a team. I want all students to get familiar with Tinkercad and 3D printing, but as they start designing to help someone in need, they work as a team”. Becky Wynne, MMS PLTW/STEM teacher at Maryville Middle School

“I’ve done a combination of both. Individual is nice but then you have way too many projects to print. Usually I select the top projects to print. Group work cuts down on the number of projects to print”. Kevin Bartok, Design Technology Teacher at the British International School Ho Chi Minh City

“Working in teams is the ideal way for students to work on 3D printing projects the majority of the time. Collaboration is a skill students need. They need to learn how to compromise when necessary and learn from each other. One person on a team might be more technically proficient while the other might be stronger when it comes to creating ideas or that might be the best person to work with the end user to refine the purpose behind the final solution”. Steven Jones, STEM/STEAM Specialist at Arlington Public Schools

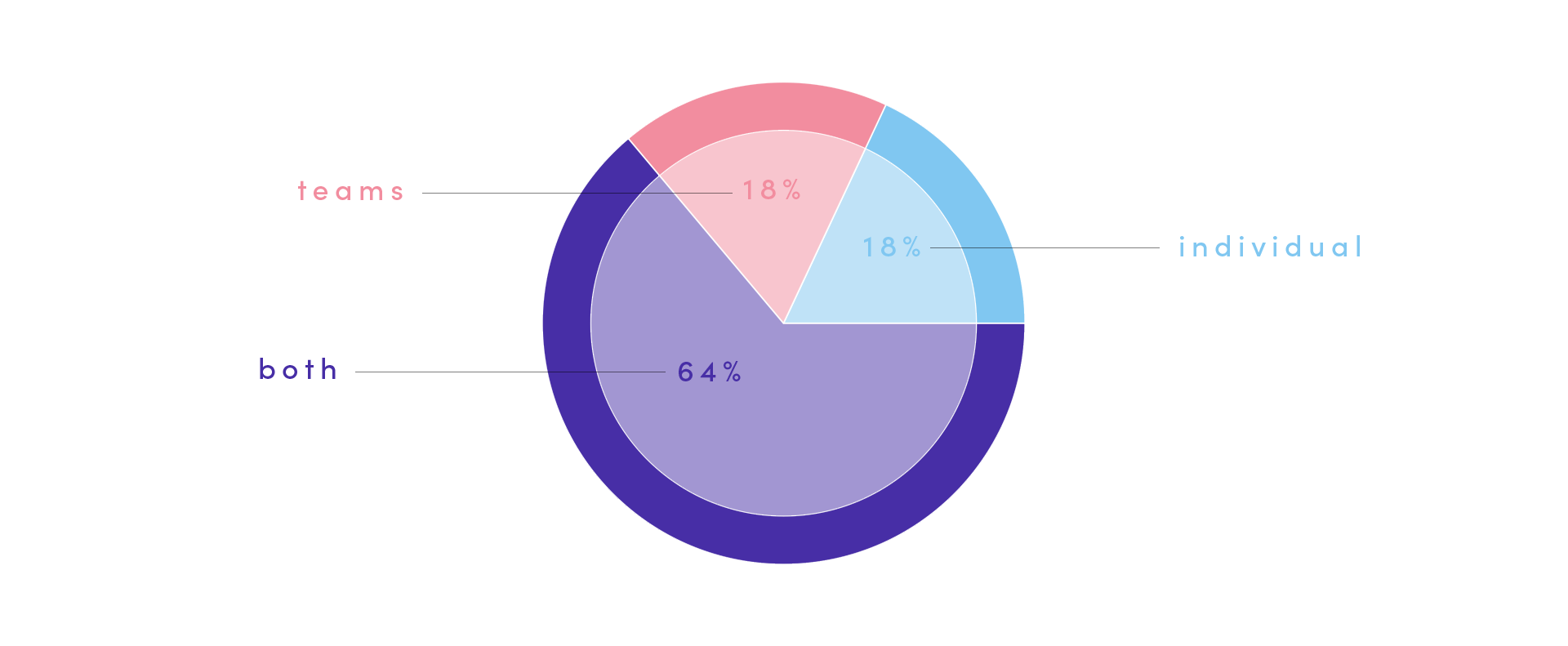

Q4: Who prepares 3D prints in slicing software?

“Slicing is an art and a science in itself. I teach the basics to kids and some really get into it. But, to keep the flow going in the print queue, my assistant and I often do the slicing now”. Linda Dimitrov, МSHS D & T teacher at Anglo-American School of Sofia

“Yes, I normally check them and give feedback before they go to print”. Todd Cleeland, STEM Teacher at Cowes Primary School

“Usually the teacher slices the model, but students have input. The primary reason behind it is that students can’t do it from their devices. Also, students typically aren’t in the classroom when their design is ready to be sliced and printed”. Steven Jones, STEM/STEAM Specialist at Arlington Public Schools

“As students bring their own devices in to school we generally request students to slice their own design, introducing students to the process in year 7 they become more confident in using it in later years”. Nicholas Sharman, Head of Design Technology & Engineering at Wimbledon High School

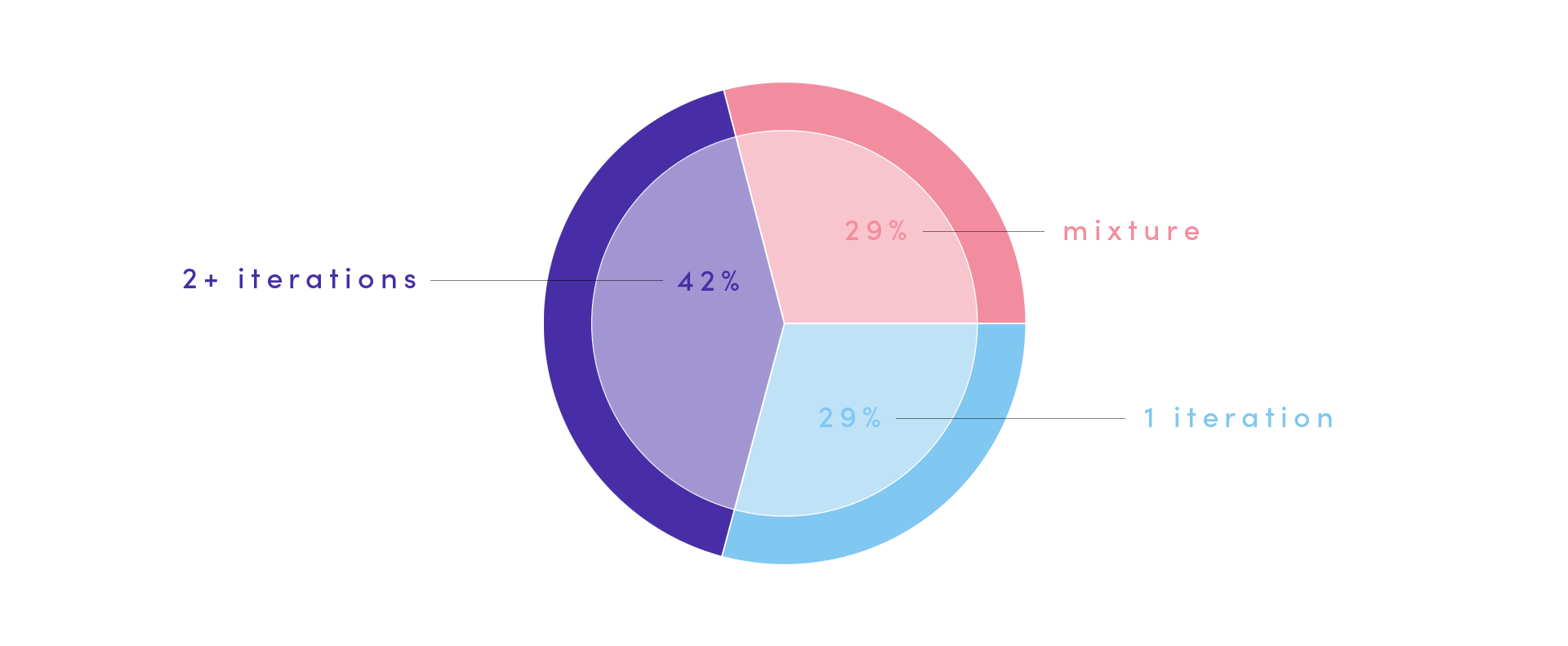

Q5: In a typical 3D printing project, how many iterations do students generally go through?

“Usually 1 due to time constraints. I’d love to get around to the second print but often there’s not enough time in a school term”. Russel Ayres, STEM leader and ICT mentor at the Southport School

“We typically start with sketching and then “CAD” (cardboard aided design) before printing. Once printed, student’s will complete another iteration or at least sketch one out”. Patrick Benfield, Innovation Director at Magellan School

“Many. But as few as possible when 3D printing. Broadly speaking we move from paper, to cardboard, to clay and then onto 3D CAD. The intention is that they make the mistakes early on and quickly – a fail fast mantra. As I said before, we insist they also make cuts of the main model to test key features and tolerances. Vase mode (spiral vase) is also very useful for some aesthetic models”. Ed Charlwood, Head of Design & Technology at Nottingham High School

“Usually 2 iterations – sometimes more. Analysis of the prints/prototypes/models is so important, get feedback via testing, checklists or from the “client” and then an attempt at improvement are so important. Sometimes this can be really challenging in terms of time constraints. I have found that preparing readiness checklists for the kids to take themselves through prior to running that first print is really useful”. Linda Dimitrov, МSHS D & T teacher at Anglo-American School of Sofia

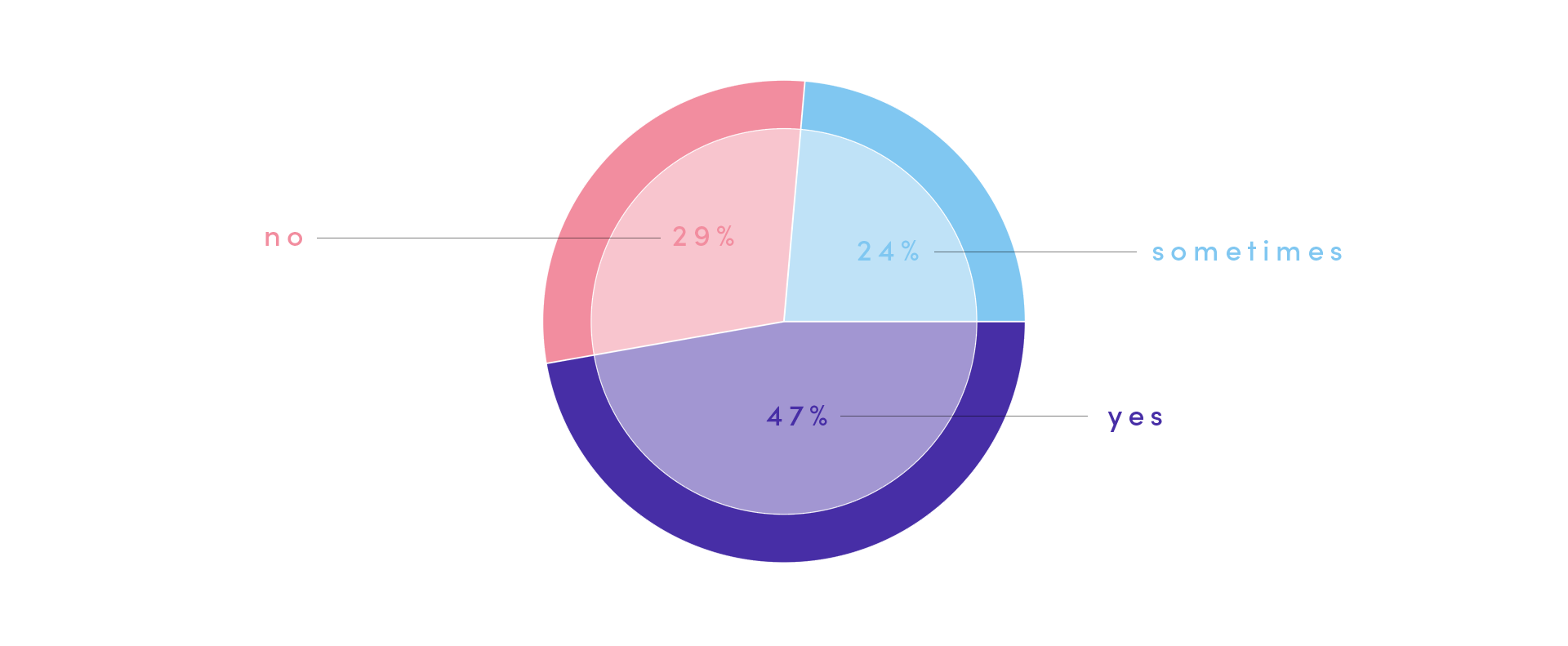

Q6: Do you generally provide constraints to students in terms of the size or print time of their 3D models?

“Yes, this allows me to have an understanding of how much material they will need and the time that it could take for the print to be completed”. Jonathan Walker, Design and Technology Teacher at Westholme School

“Everything depends on the projects. Oftentimes we put constraints on the size so that it can print in a fairly reasonable amount of time. The density is what we usually manipulate to make it shorter”. Michael Mun, Teacher at Edmonton Public School Board

“Yes, I generally do provide constraints for size/print time. I only have two functional printers, and teaching 2-4 classes at a time that may be using the printers, so I need things to print relatively quickly. I find it also adds a bit of challenge to the design to have certain criteria that needs to be met”. Becky Wynne, MMS PLTW/STEM teacher at Maryville Middle School

“I have had to more and more. I am teaching far more classes this year and keeping the projects rolling through the printers means constraints are necessary”. Linda Dimitrov, МSHS D & T teacher at Anglo-American School of Sofia

Q7: Do you allow students to choose what type of material and what colour they use for their 3D prints?

“In our school we only use PLA filament. I will give students choice if it is a personal item. I keep the choice to the colors I have on the 3 printers we generally use. I don’t typically change out filament for color”. Ron Nober, Technology/STEAM Teacher at Southampton Township Schools

“I only use PLA for the material since it is easier to handle and reliable but they can use any color available at the time”. Gurbey Demirturk, Engineering/CTE Curriculum Developer at Harmony Public Schools

“In most cases they can’t choose because not all projects require the use of specialized filaments and changing the filament based on individual color preference is not the best use of time. As with everything else, time needs to be maximized to benefit the whole group”. Steven Jones, STEM/STEAM Specialist at Arlington Public Schools

“Yes, project color is the teams choice. We mostly print with PLA, although we have used PETG on one project”. Lynette Curzon, EAST Facilitator at Westwood Elementary

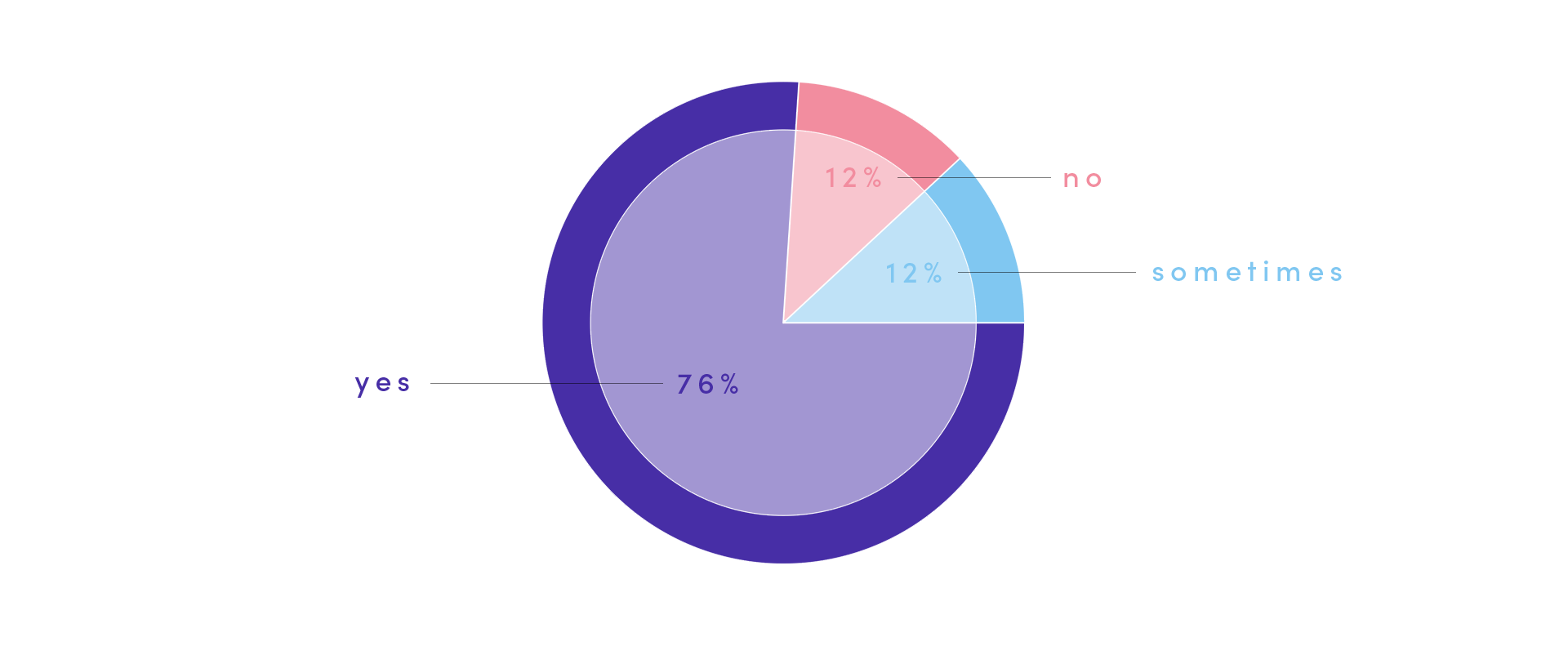

Q8: Do you (or anyone else) check student’s 3D models prior to 3D printing?

“For our MYP students, we check their first several prints. As they gain more experience, then we’ll check on request. For PYP students, we check more frequently. We also will check their model and even if we know it will likely fail or have issues, don’t tell the student and have them print anyway, so that can learn to troubleshoot”. Patrick Benfield, Innovation Director at Magellan School

“Yes. Teachers or technicians do. We also encourage peer checking”. Ed Charlwood, Head of Design & Technology at Nottingham High School

“Other students critique student models first before I check them. Once students have enough knowledge and experience, I trust them to critique each other prior to printing in order to save time. I can spend less time scrutinizing a design if I know that it has been checked by three peers first that understand the criteria and constraints of the project”. Steven Jones, STEM/STEAM Specialist at Arlington Public Schools

“Yes, I check them and so do the 3D printing operators. I have intentionally let them miss things such as a project floating above work plane so they can see what happens on the 3D printer side. We embrace mistakes and oversights in the EAST room! Just as well because they are coming anyway :)”. Lynette Curzon, EAST Facilitator at Westwood Elementary

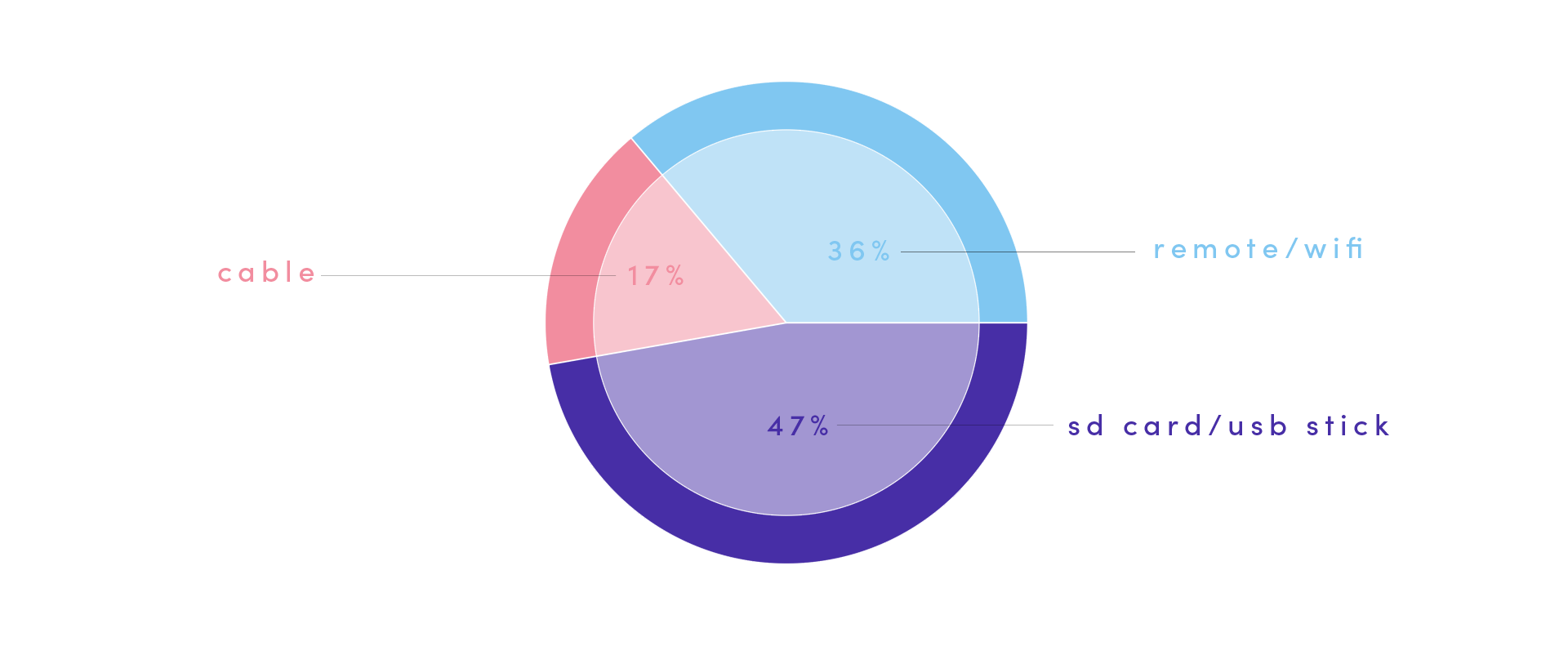

Q9: How do you send models to your 3D printer?

“We use a USB cable as students are able to connect their own devices”. Nicholas Sharman, Head of Design Technology & Engineering at Wimbledon High School

“For the Ultimaker 3, S3, and the Toybox, models are all sent via wifi. This is a much more convenient and efficient for our students to do this. Saving as gcode and then managing SD cards with so many students adds another layer of complexity to an already complex process, plus all of the other digital fabrication tools students are working with”. Patrick Benfield, Innovation Director at Magellan School

“I use a USB for the Ultimaker printers and a SD card for the Prusa printers”. Jim Cairns, Engineering Design Teacher at Bellevue Christian School

“Models are usually sent to the printer over WiFi as long as the network is operational. A USB flash drive can be used as a backup, but it is rarely needed”. Steven Jones, STEM/STEAM Specialist at Arlington Public Schools

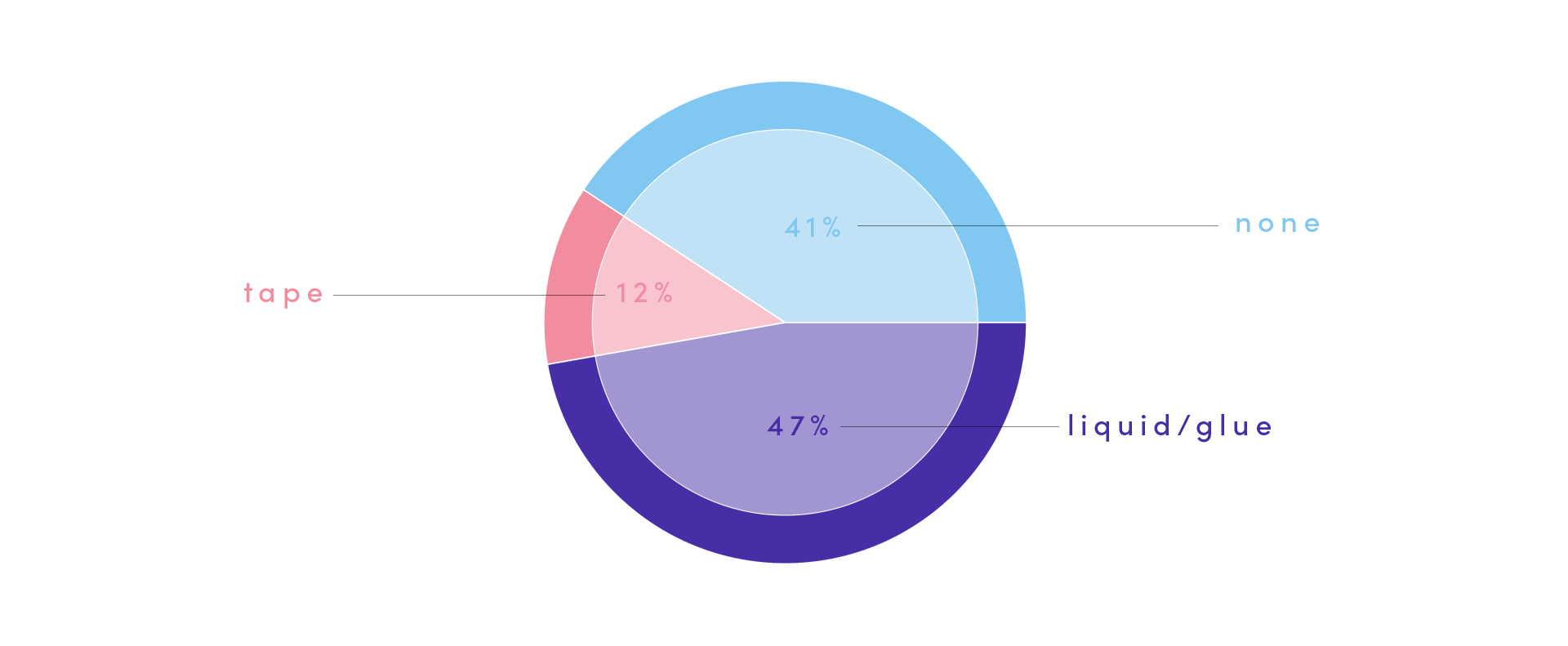

Q10: Do you use any products to help models stick to the print bed?

“Typically, no. We used to apply glue stick adhesive to the print bed, but the buildup and cleaning was taking too much time. We now just print directly on the heated glass build plate and after every few prints, clean the class with alcohol wipes to remove any finger print oils and that has worked fine”. Patrick Benfield, Innovation Director at Magellan School

“I used to in the early days of learning to 3D print objects. I mostly used blue painters tape. The EAST program purchased printers from a local group of guys that built their own. These guys have moved on to other things so I moved on too. I have ultimakers and flashforges. These machines can get a more precise leveling and I am better at knowing what a project needs so I don’t use any additional products for printing”. Lynette Curzon, EAST Facilitator at Westwood Elementary

“Yes, we use glue to help it stick to the glass”. Todd Cleeland, STEM Teacher at Cowes Primary School

“I use hairspray for the Ultimaker 3 printers which are on a glass bed. I also wash the beds in soap and water once a year”. Jim Cairns, Engineering Design Teacher at Bellevue Christian School

—

As we mentioned at the beginning of the post, there are a huge variety of answers, which were dependent on a whole range of factors, including:

- Personal preference

- Time

- Budget and equipment

- Age and skill level of students

- Health and safety

We hope you found the data as insightful as we did and a big thank you to all our pioneers who participated in this study. We’ll be sharing more pioneer insights soon!